Ring Joint Gaskets

Ring Joint GasketA solid metal gasket that is softer than the mating flange material that is virtually ‘crushed’ into the flange face, creating a seal by filling imperfections and leak paths with gasket material. Under high sealing stress the gasket deforms but not the flange. They are used predominantly in the petrochemical industry (offshore oil platforms, refineries) due to the high service pressures required in their processes. Ring joint gaskets are machined to exact specifications and tight tolerances and come in a number of styles.

Ring Joint Gasket Styles

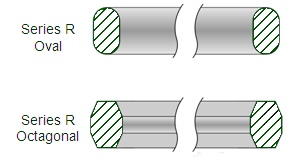

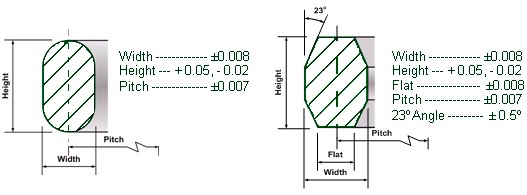

R Oval or octagonal

RX Self-energizing gasket

BX Used in API spec 6A flanges

Materials

Common materials used for the manufacture of ring joint gaskets:

·Soft Iron

·Low Carbon Steel

·Stainless Steel

·Monel®

·Inconel®

·Incoloy®

·Hastelloy®

Hardness of Materials

On compression of the flange assembly, it is imperative that the ring joint gasket be significantly softer than the flange groove so that the gasket plastically deforms and not the groove. The use of harder ring joint gaskets can result in flange groove damage. For this reason, ring joint gaskets are supplied with the following maximum hardness values:

| Material | HB Max. | HRB Max. |

| Soft Iron | 90 | 56 |

| Low Carbon Steel | 120 | 68 |

| 5Cr1/2Mo | 130 | 72 |

| 304 SS | 160 | 83 |

| 316 SS | 160 | 83 |

| 347 SS | 160 | 83 |

| 410 SS | 170 | 86 |

The type R oval configuration is the original ring joint design followed by the type R octagonal. Both styles are interchangeable on the modern flat bottom groove, however only the oval style can be used in the old type round bottom groove. Style R ring type joints are designed to seal pressure up to 6,250 psi in accordance with ASME B16.5 pressure ratings and up to 5,000 psi in accordance with API 6A pressure ratings.

|

|

|

Series 'R' manufactured to the standards ASME B 16.20 - API Spec. 6A BS EN 12560-5

Dimensions in inch

| Gasket Dimensions | ANSI | ANSI | ANSI | API | ANSI | API | ANSI | API | ANSI | |||||

| Ring No. | Pitch | Width | Height | W of Flat | 150 | 300 | 600 | 2000# | 900 | 3000# | 1500 | 5000# | 2500 | |

| Oval | Oct | Nominal Pipe Size | ||||||||||||

| R11 | 1.344 | 0.250 | 0.440 | 0.380 | 0.170 | 1/2 | 1/2 | |||||||

| R12 | 1.563 | 0.313 | 0.560 | 0.500 | 0.206 | 1/2 | 1/2 | |||||||

| R13 | 1.688 | 0.313 | 0.560 | 0.500 | 0.206 | 3/4 | 3/4 | 1/2 | ||||||

| R14 | 1.750 | 0.313 | 0.560 | 0.500 | 0.206 | 3/4 | 3/4 | |||||||

| R15 | 1.875 | 0.313 | 0.560 | 0.500 | 0.206 | 1 | ||||||||

| R16 | 2.000 | 0.313 | 0.560 | 0.500 | 0.206 | 1 | 1 | 1 | 1 | 3/4 | ||||

| R17 | 2.250 | 0.313 | 0.560 | 0.500 | 0.206 | 1-1/4 | ||||||||

| R18 | 2.375 | 0.313 | 0.560 | 0.500 | 0.206 | 1-1/4 | 1-1/4 | 1-1/4 | 1-1/4 | 1 | ||||

| R19 | 2.563 | 0.313 | 0.560 | 0.500 | 0.206 | 1-1/2 | ||||||||

| R20* | 2.688 | 0.313 | 0.560 | 0.500 | 0.206 | 1-1/2 | 1-1/2 | 1-1/2 | 1-1/2 | |||||

| R21 | 2.844 | 0.438 | 0.690 | 0.630 | 0.305 | 1-1/4 | ||||||||

| R22 | 3.250 | 0.313 | 0.560 | 0.500 | 0.206 | 2 | ||||||||

| R23* | 3.250 | 0.438 | 0.690 | 0.630 | 0.305 | 2 | 2 | 2-1/16 | 1-1/2 | |||||

| R24* | 3.750 | 0.438 | 0.690 | 0.630 | 0.305 | 2 | 2-1/16 | 2 | 2-1/16 | |||||

| R25 | 4.000 | 0.313 | 0.560 | 0.500 | 0.206 | 2-1/2 | ||||||||

| R26* | 4.000 | 0.438 | 0.690 | 0.630 | 0.305 | 2-1/2 | 2-1/2 | 2-9/16 | 2 | |||||

| R27* | 4.250 | 0.438 | 0.690 | 0.630 | 0.305 | 2-1/2 | 2-9/16 | 2-1/2 | 2-9/16 | |||||

| R28 | 4.375 | 0.500 | 0.750 | 0.690 | 0.341 | 2-1/2 | ||||||||

| R29 | 4.500 | 0.346 | 0.560 | 0.500 | 0.206 | 3 | ||||||||

| R30 | 4.625 | 0.438 | 0.690 | 0.630 | 0.305 | 3 | 3 | |||||||

| R31* | 4.875 | 0.438 | 0.690 | 0.630 | 0.305 | 3 | 3 | 3-1/8 | 3 | 3-1/8 | ||||

| R32 | 5.000 | 0.500 | 0.750 | 0.690 | 0.341 | 3 | ||||||||

| R33 | 5.188 | 0.313 | 0.560 | 0.500 | 0.206 | 3-1/2 | ||||||||

| R34 | 5.188 | 0.438 | 0.690 | 0.630 | 0.305 | 3-1/2 | 3-1/2 | |||||||

| R35* | 5.375 | 0.438 | 0.690 | 0.630 | 0.305 | 3 | 3-1/8 | |||||||

| R36 | 5.875 | 0.313 | 0.560 | 0.500 | 0.206 | 4 | ||||||||

| R37* | 5.875 | 0.438 | 0.690 | 0.630 | 0.305 | 4 | 4 | 4-1/16 | 4 | 4-1/16 | ||||

| R38 | 6.188 | 0.625 | 0.880 | 0.810 | 0.413 | 4 | ||||||||

| R39* | 6.375 | 0.438 | 0.690 | 0.630 | 0.305 | 4 | 4-1/16 | |||||||

| R40 | 6.750 | 0.313 | 0.560 | 0.500 | 0.206 | 5 | ||||||||

| R41* | 7.125 | 0.438 | 0.690 | 0.630 | 0.305 | 5 | 5 | 5-1/8 | 5 | 5-1/8 | ||||

| R42 | 7.500 | 0.750 | 1.000 | 0.940 | 0.485 | 5 | ||||||||

| R43 | 7.625 | 0.313 | 0.560 | 0.500 | 0.206 | 6 | ||||||||

| R44* | 7.625 | 0.438 | 0.690 | 0.630 | 0.305 | 5 | 5-1/8 | |||||||

| R45* | 8.313 | 0.438 | 0.690 | 0.630 | 0.305 | 6 | 6 | 7-1/16 | 6 | 7-1/16 | ||||

| R46* | 8.313 | 0.500 | 0.750 | 0.690 | 0.341 | 6 | 7-1/16 | |||||||

| R47* | 9.000 | 0.750 | 1.000 | 0.940 | 0.485 | 6 | ||||||||

| R48 | 9.750 | 0.313 | 0.560 | 0.500 | 0.206 | 8 | ||||||||

| R49* | 10.625 | 0.438 | 0.690 | 0.630 | 0.305 | 8 | 8 | 9 | 8 | 9 | ||||

| R50* | 10.625 | 0.625 | 0.880 | 0.810 | 0.413 | 8 | 9 | |||||||

| R51 | 11.000 | 0.875 | 1.130 | 1.060 | 0.583 | 8 | ||||||||

| R52 | 12.000 | 0.313 | 0.560 | 0.500 | 0.206 | 10 | ||||||||

| R53* | 12.750 | 0.438 | 0.690 | 0.630 | 0.305 | 10 | 10 | 11 | 10 | 11 | ||||

| R54* | 12.750 | 0.625 | 0.880 | 0.810 | 0.413 | 10 | 11 | |||||||

| R55 | 13.500 | 1.125 | 1.440 | 1.380 | 0.780 | 10 | ||||||||

| R56 | 15.000 | 0.313 | 0.560 | 0.500 | 0.206 | 12 | ||||||||

| R57* | 15.000 | 0.438 | 0.690 | 0.630 | 0.305 | 12 | 12 | 13-5/8 | 12 | 13-5/8 | ||||

| R58 | 15.000 | 0.875 | 1.130 | 1.060 | 0.583 | 12 | ||||||||

| R59 | 15.625 | 0.313 | 0.560 | 0.500 | 0.206 | 14 | ||||||||

| R60 | 16.000 | 1.250 | 1.560 | 1.500 | 0.879 | 12 | ||||||||

| R61 | 16.500 | 0.438 | 0.690 | 0.630 | 0.305 | 14 | 14 | |||||||

| R62 | 16.500 | 0.625 | 0.880 | 0.810 | 0.413 | 14 | ||||||||

| R63* | 16.500 | 1.000 | 1.310 | 1.250 | 0.681 | 14 | ||||||||

| R64 | 17.875 | 0.313 | 0.560 | 0.500 | 0.206 | 16 | ||||||||

| R65* | 18.500 | 0.438 | 0.690 | 0.630 | 0.305 | 16 | 16 | 16-3/4 | ||||||

| R66* | 18.500 | 0.625 | 0.880 | 0.810 | 0.413 | 16 | 16-3/4 | |||||||

| R67 | 18.500 | 1.125 | 1.440 | 1.380 | 0.780 | 16 | ||||||||

| R68 | 20.375 | 0.313 | 0.560 | 0.500 | 0.206 | 18 | ||||||||

| R69* | 21.000 | 0.438 | 0.690 | 0.630 | 0.305 | 18 | 18 | |||||||

| R70* | 21.000 | 0.750 | 1.000 | 0.940 | 0.485 | 18 | ||||||||

| R71 | 21.000 | 1.125 | 1.440 | 1.380 | 0.780 | 18 | ||||||||

| R72 | 22.000 | 0.313 | 0.560 | 0.500 | 0.206 | 20 | ||||||||

| R73* | 23.000 | 0.500 | 0.750 | 0.690 | 0.641 | 20 | 20 | 21-1/4 | ||||||

| R74* | 23.000 | 0.750 | 1.000 | 0.940 | 0.485 | 20 | 21-1/4 | |||||||

| R75 | 23.000 | 1.250 | 1.560 | 1.500 | 0.879 | 20 | ||||||||

| R76 | 26.500 | 0.313 | 0.560 | 0.500 | 0.206 | 24 | ||||||||

| R77 | 27.250 | 0.625 | 0.880 | 0.810 | 0.413 | 24 | 24 | |||||||

| R78 | 27.250 | 1.000 | 1.310 | 1.250 | 0.681 | 24 | ||||||||

| R79 | 27.250 | 1.375 | 1.750 | 1.630 | 0.977 | 24 | ||||||||

| R80 | 24.250 | 0.313 | 0.500 | 0.206 | 22 | |||||||||

| R81 | 25.000 | 0.563 | 0.750 | 0.377 | 22 | 22 | ||||||||

| R82* | 2.250 | 0.438 | 0.630 | 0.305 | ||||||||||

| R84* | 2.500 | 0.438 | 0.630 | 0.305 | ||||||||||

| R85* | 3.125 | 0.500 | 0.690 | 0.341 | ||||||||||

| R86* | 3.563 | 0.625 | 0.810 | 0.413 | ||||||||||

| R87* | 3.938 | 0.625 | 0.810 | 0.413 | ||||||||||

| R88* | 4.875 | 0.750 | 0.940 | 0.485 | ||||||||||

| R89* | 4.500 | 0.750 | 0.940 | 0.485 | ||||||||||

| R90* | 6.125 | 0.875 | 1.060 | 0.583 | ||||||||||

| R91* | 10.250 | 1.250 | 1.500 | 0.879 | ||||||||||

| R92 | 9.000 | 0.438 | 0.630 | 0.305 | ||||||||||

| R93 | 29.500 | 0.750 | 0.690 | 0.940 | 0.485 | 26 | 26 | |||||||

| R94 | 31.500 | 0.750 | 0.940 | 0.485 | 28 | 28 | ||||||||

| R95 | 33.750 | 0.750 | 0.940 | 0.485 | 30 | 30 | ||||||||

| R96 | 36.000 | 0.875 | 1.060 | 0.583 | 32 | 32 | ||||||||

| R97 | 38.000 | 0.875 | 1.060 | 0.583 | 34 | 34 | ||||||||

| R98 | 40.250 | 0.875 | 1.060 | 0.583 | 36 | 36 | ||||||||

| R99* | 9.250 | 0.438 | 0.630 | 0.305 | ||||||||||

| R100 | 29.500 | 1.125 | 1.380 | 0.780 | 26 | |||||||||

| R101 | 31.500 | 1.250 | 1.500 | 0.879 | 28 | |||||||||

| R102 | 33.750 | 1.250 | 1.500 | 0.879 | 30 | |||||||||

| R103 | 36.000 | 1.250 | 1.500 | 0.879 | 32 | |||||||||

| R104 | 38.000 | 1.375 | 1.630 | 0.977 | 34 | |||||||||

| R105 | 40.250 | 1.375 | 1.630 | 0.977 | 36 | |||||||||

RX Style Ring Joint Gaskets

The Style RX ring type joint is manufactured in accordance with API 6A and ASME B16.20, to suit API 6B and ASME B16.5 flanges. The Style RX is designed to fit the modern flat bottom groove, and is interchangeable with the standard Style R ring type joint. However, since the Style RX is significantly taller than a Style R, larger flange make up distances will result. Style RX ring type joints are designed to seal pressures up to 6,250 psi in accordance with ASME B16.5 pressure ratings, and up to 5,000 psi in accordance with API 6A pressure ratings. Selected sizes incorporate a pressure passage hole to allow for pressure equalization each side of the sealing faces.

|

|

|

A ---------------- + 0.008, - 0.000

H ---------------- + 0.008, - 0.000

OD -------------- + 0.010, - 0.000

C ---------------- + 0.006, - 0.000

D ---------------- + 0.000, - 0.030

E ----------------± 0.02

23o ------------ ± 1/2o

Series 'RX' manufactured to the standards ASME B 16.20 - API Spec. 6A

Dimensions in inch

| Gasket Dimensions | Class | |||||

| Ring No. | ID | OD | Height | 2000 | 3000 | 5000 |

| Nominal Pipe Size | ||||||

| RX20 | 2.313 | 3.000 | 0.750 | 1-1/2 | 1-1/2 | |

| RX23 | 2.672 | 3.672 | 1.000 | 2 | ||

| RX24 | 3.234 | 4.172 | 1.000 | 2 | 2 | |

| RX25 | 3.625 | 4.313 | 0.750 | 3-1/8 | ||

| RX26 | 3.469 | 4.406 | 1.000 | 2-1/2 | ||

| RX27 | 3.719 | 4.656 | 1.000 | 2-1/2 | 2-1/2 | |

| RX31 | 4.359 | 5.297 | 1.000 | 3 | 3 | |

| RX35 | 4.859 | 5.797 | 1.000 | 3 | ||

| RX37 | 5.359 | 6.297 | 1.000 | 4 | 4 | |

| RX39 | 5.859 | 6.797 | 1.000 | 4 | ||

| RX41 | 6.609 | 7.547 | 1.000 | 5 | 5 | |

| RX44 | 7.109 | 8.047 | 1.000 | 5 | ||

| RX45 | 7.797 | 8.734 | 1.000 | 6 | 6 | |

| RX46 | 7.688 | 8.75 | 1.125 | 6 | ||

| RX47 | 8.094 | 9.656 | 1.625 | 8 | ||

| RX49 | 10.109 | 11.047 | 1.000 | 8 | 8 | |

| RX50 | 9.844 | 11.156 | 1.250 | 8 | ||

| RX53 | 12.234 | 13.172 | 1.000 | 10 | 10 | |

| RX54 | 11.969 | 13.281 | 1.250 | 10 | ||

| RX57 | 14.484 | 15.422 | 1.000 | 12 | 12 | |

| RX63 | 15.266 | 17.391 | 2.000 | 14 | ||

| RX65 | 17.984 | 18.922 | 1.000 | 16 | ||

| RX66 | 17.719 | 19.031 | 1.250 | 16 | ||

| RX69 | 20.484 | 21.422 | 1.000 | 18 | ||

| RX70 | 20.094 | 21.656 | 1.625 | 18 | ||

| RX73 | 22.406 | 23.469 | 1.250 | 20 | ||

| RX74 | 22.094 | 23.656 | 1.625 | 20 | ||

| RX99 | 8.734 | 9.672 | 1.000 | 8 | 8 | |

| RX201 | 1.573 | 2.026 | 0.445 | 1-3/8 | ||

| RX205 | 2.016 | 2.453 | 0.437 | 1-13/16 | ||

| RX210 | 3.094 | 3.844 | 0.750 | 2-9/16 | ||

| RX215 | 4.609 | 5.547 | 1.000 | 4-1/16 | ||

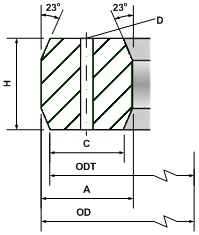

BX Style Ring Joint Gasket

The Style BX ring type joint is manufactured in accordance with API 6A. All BX ring type joints incorporate a pressure passage hole to allow for pressure equalization each side of the sealing faces. On assembly, metal to metal contact of the flange faces is achieved. The Style BX is not interchangeable with any other style, and is only suited for API 6BX flanges. Style BX ring type joints are designed to seal pressure up to 20,000 psi in accordance with API 6A pressure ratings.

|

|

|

Tolerances

A ---------------- + 0.008, - 0.000

H ---------------- + 0.008, - 0.000

D --------------- ± 0.02

OD -------------- + 0.000, - 0.005

ODT ----------- ± 0.002

C ---------------- + 0.006, - 0.000

23o ------------ ± 1/4o

Series 'BX' manufactured to the standards ASME B 16.20 - API Spec. 6A

Dimensions in inch

| Gasket Dimensions | Class | ||||||||

| Ring No. | ID | OD | Height | 2000 | 3000 | 5000 | 10000 | 15000 | 20000 |

| Nominal Pipe Size | |||||||||

| BX151 | 2.250 | 3.008 | 0.379 | 1-13/16 | 1-13/16 | 1-13/16 | |||

| BX152 | 2.528 | 3.334 | 0.403 | 2-1/16 | 2-1/16 | 2-1/16 | |||

| BX153 | 3.078 | 3.974 | 0.448 | 2-9/16 | 2-9/16 | 2-9/16 | |||

| BX154 | 3.624 | 4.600 | 0.488 | 3-1/16 | 3-1/16 | 3-1/16 | |||

| BX155 | 4.705 | 5.825 | 0.560 | 4-1/16 | 4-1/16 | 4-1/16 | |||

| BX156 | 7.901 | 9.637 | 0.733 | 7-1/16 | 7-1/16 | 7-1/16 | |||

| BX157 | 9.941 | 11.593 | 0.826 | 9 | 9 | 9 | |||

| BX158 | 12.038 | 13.890 | 0.911 | 11 | 11 | 11 | |||

| BX159 | 14.776 | 16.800 | 1.012 | 13-5/8 | 13-5/8 | 13-5/8 | |||

| BX160 | 14.768 | 15.850 | 0.938 | 13-5/8 | |||||

| BX162 | 17.600 | 18.720 | 0.560 | 16-3/4 | 16-3/4 | ||||

| BX163 | 20.528 | 21.896 | 1.185 | 18-3/4 | |||||

| BX164 | 20.527 | 22.463 | 1.185 | 18-3/4 | 18-3/4 | ||||

| BX165 | 23.139 | 24.595 | 1.261 | 21-1/4 | |||||

| BX166 | 23.140 | 25.198 | 1.261 | 21-1/4 | |||||

| BX167 | 28.864 | 29.896 | 1.412 | 26-3/4 | |||||

| BX168 | 28.864 | 30.138 | 1.412 | 26-3/4 | |||||

| BX169 | 5.813 | 6.831 | 0.624 | 5-1/8 | 5-1/8 | ||||

| BX303 | 32.237 | 33.573 | 1.494 | 30 | 30 | ||||

Ordering Information

When ordering ring joint gaskets please specify the following:

·Gasket style and number

·Material

·Nominal pipe size and pressure rating or specific gasket dimensions if other than standard

| Home | News | Products | Swages | Oil Country | Couplings | Spec Blinds | Gapalets | Ring Gaskets | Needle Valves | Pressure Gauges | Hammer Unions | Swivel Joints | API Flanges | Chokes | Catalogues |

Send mail to Webmaster

with questions or comments about this web site.

Copyright © 2024 Vengeance Oilfield Products Inc